| FINAL

REPORT - THE PASSIVE IGLOO PROJECT |

The passive igloo - Nanuq Greenland, spring 2016 (photo Peter

Gallinelli)

The

passive igloo project

Feedback

from an Arctic winter in a self-sufficient passive habitat

Peter

Gallinelli

Association ACAPELA, Geneva, Switzerland

© 2017

Table of contents

Abstract

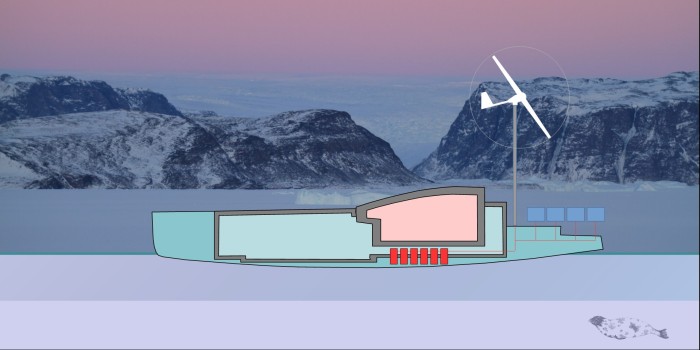

The aim of the passive igloo project is to explore the possibilities

of creating an ecological and self-sufficient habitat by using

sound constructive measures and renewable energy resources

to guarantee thermal comfort in the most severe cold climates.

The passive igloo is a self-sufficient housing module

built into a polar exploration sailboat to accommodate a crew

of 2 to 6 people in conditions of severe cold to live and

work. In order to test the passive igloo, the boat was voluntarily

trapped in the ice in North West Greenland during the winter

of 2015-2016 and monitored during the 10 months of 'stationary

navigation'.

The passive igloo, the main living space

(photo Dorothée Adam)

Evidence has been provided that it is possible to create

an almost self-sufficient habitat while remaining simple and

affordable, even in the Arctic climate.

The biggest unforeseen event was the lack of wind that should

have been the main source of energy during the Arctic night.

Nevertheless the experiment could be concluded, making it

possible to point out that when a system requires very little

resources to operate it is intrinsically resilient and therefore

safe.

The passive igloo project goes beyond the issue

of energy self-sufficiency and also addresses complementary

aspects that are no less vital such as food, water or waste

management. It becomes a most complete laboratory of autonomy.

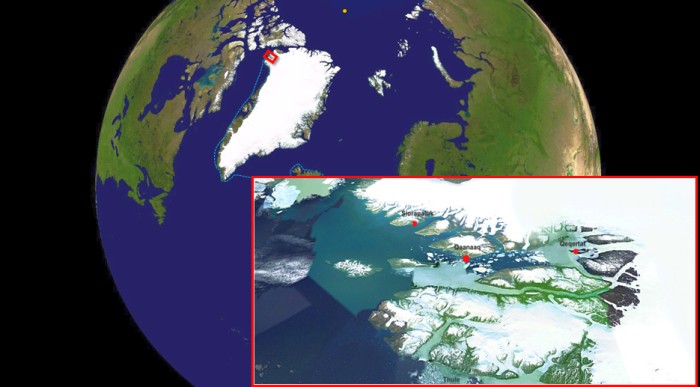

Location and climate

Located at 77.5 ° latitude north at a distance of 1200

km from the North Pole, the place for the winter camp provided

good chances of a harsh winter with temperatures that would

allow to test the systems to their ultimate limit, or even

beyond, with temperatures between -30° C and -40°

C and in the total absence of sun ... but also the remoteness

required to make self-sufficiency a real challenge and a total

commitment meaning that the systems would have to be absolutely

reliable.

Image background : NASA bluemarble (c)

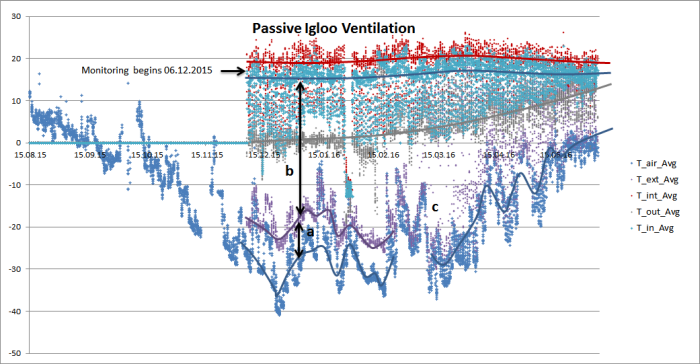

The graph

below shows air temperatures and heating degree days from

mid-September 2015 to June 2016.

Winter 2015-2016 ; overview indoor

and outdoor air temperatures; HD: heating degree days 20/12

= 11800 dK; T-cabin / -3 = 7200 dK; for comparison in Central

Europe / Switzerland there are ~ 3000 heating degree days.

During the winter, the seawater temperature was almost constant

at -1.6° C, under the sea ice.

Given the very low temperatures, the air was extremely dry

which limits the snowfall: 20cm accumulated from the beginning

of the winter until March. Only with the warming of the spring,

rainfall added 30cm of fresh snow during the month of April.

At the location of the winter camp, winds were strongest

between September and October, punctuated by violent storms

with speeds in excess of 70 knots. Overall, the winds, however,

remained weak and weren't a sufficient and reliable enough

as a source of energy. Part of the contradiction lies in providing

a safe and sheltered place for the boat to stay and at the

same time exposed to run the wind generators.

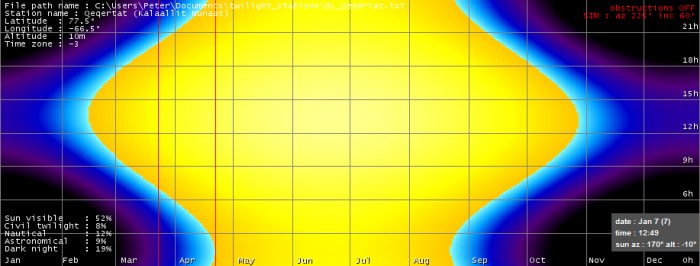

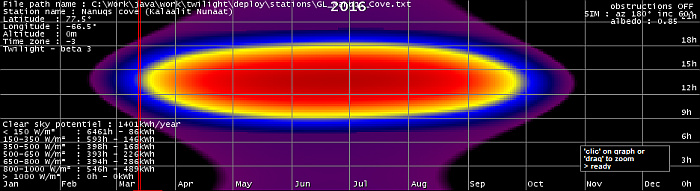

Located far above the Arctic Circle, the sun is completely

absent from late October to mid-February and despite significant

twilights, solar energy during this period is close to zero.

However, this absence is compensated by a four-month summer

period during which the sun does not set, associated with

clear weather and enjoying a strong reverberation due to the

ice and snow, contributory to the use of solar energy.

Twilight and sunshine hours in Qeqertat

- horizontal axis = date; vertical axis = hour (application

'twilight' - Peter Gallinelli)

Monitoring

In order to provide not only qualitative but also quantitative

feedback, a monitoring system was installed. It consisted

of two Campbell CR1000 automatic acquisition units equipped

with ad-hoc sensors and a microcontroller.

The climate station; at the end of winter

the ice begins to melt away (photo Peter Gallinelli)

Outside - weather station :

- air temperature

- global horizontal and reflected solar radiation (albedo)

- ice surface temperature and water temperature at 3m depth

- heat flux through ice shelf

- wind direction and speed

Inside :

- living quarters, cabin and bilge air temperature

- inlet and exhaust air temperatures of ventilation system

- relative humidity of cabin air

- heat flux sensor (mobile)

- diesel flow meter

- portable CO2 sensor

- atmospheric pressure

The extreme conditions resulted in several power failures

and consecutive measurement holes. The marine environment

did not allow to deploy all the probes during the whole stay

(e.g. the land based weather station). In particular the severe

cold made installation and maintenance extremely difficult

and demanding.

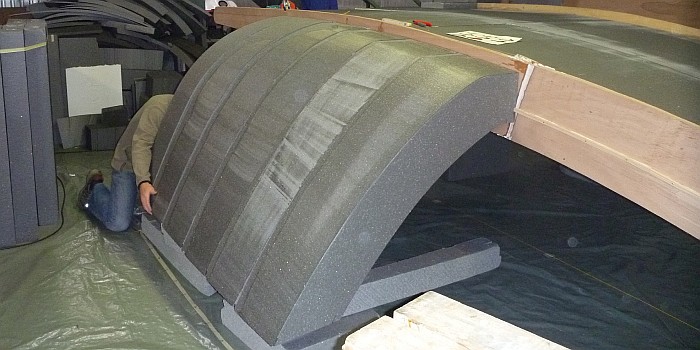

The systems

Thermal insulation : 66% of the energy consumed

corresponds to transmission heat losses

The cabin insulation consists of a structural core made of

polystyrene foam specially formulated for the project. It

is sandwiched between two fiberglass and epoxy resin skins

thus constituting a both structural and insulating component

without thermal bridges. The U value of this sandwich is 0.12

W / (m²K), a strict minimum in terms of thermal performance

and a strict maximum in terms of habitability that is particularly

constrained on a boat, especially due to reduced cabin height.

The passive igloo during construction.

The insulation fulfils both: a role of thermal insulation

and structural . Thickness 200mm.

The windows meet the compromise of sufficient visibility

during navigation, when weather is warm, and best performance

to limit heat losses during winter. Despite their excellent

quality with a U value of 0.5 W / (m²K), their performance

remains four times less than the surrounding superstructures.

Consisting of a triple glazing with two low-e layers and an

inert gas filling, they must also withstand high mechanical

stresses (navigation), impacts, and have a bond adapted to

extreme cold.

Laminated triple glazing used for windows.

Thickness 60mm.

Despite the excellent quality of the glazing, switching off

the heating during the rest periods resulted in the formation

of frost on the glazing when the temperatures in the cabin

dropped below 5° C at the end of the night. Rather than

to heat, this phenomenon could be solved by covering the windows

with 20-40cm of snow, in the manner of an insulating blanket.

The thermal conductivity of the snow was measured to 0.1W

/ (mK), which amounts to adding about 10 cm of a conventional

insulation.

Snow: an effective and free addition.

Lambda thermal conductivity = 0.1 W / (mK). Thickness 20-40cm.

Photo in the spring (photo Peter Gallinelli)

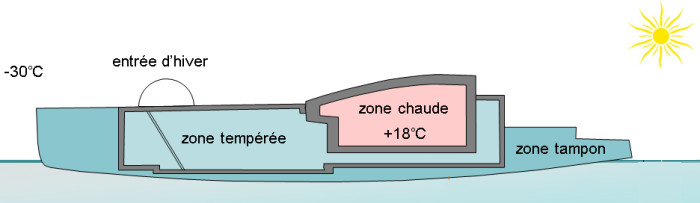

Thermal zones::

Sleeping bags being comfortable down to below -20 ° C,

the sleeping quarters remained unheated. However, the formation

of condensation and frost forced us to include them in the

heated area, causing additional heat losses. Despite this

precaution, the weaker insulation of the cabins showed dew

points as soon as the outside temperature permanently dropped

below -15 ° C, mainly in the outside corners and under

the mattresses. Thermal zoning could only be moderate. In

our case the temperature in the cabins was on average 5°

C below the temperature in the living quarters with a strong

vertical temperature stratification.

The same reason can be used to explain why unheated entrance

locks do not work in cold weather. It will be discussed later.

Thermal zoning principle

Environmental heat:

The hull being immersed in relatively warm seawater (-1.6°

C) acted as a heat input. In the absence of occupants and

activities on board, the equilibrium temperature in the living

quarters stabilized at -10° C for an outside temperature

of -20 to -25 ° C (see trip to Qaanaaq). The effect was

most noticeable at the beginning of the winter with a buffer

zone temperature (bilge) close to 0° C. This would gradually

decrease to -10° C as the thickness of pack ice increased

(close to 2m around the boat) and the hull was pushed out

of the water trough sea ice pressure (50cm), see T_bilge of

the temperature graph. The boat played a role of insulating

cover: even at the end of winter the keel was still surrounded

by liquid water.

Conclusion :

Of all the systems, thermal insulation

was the most fundamental prerequisite for the project's success.

It is an unspectacular system but the only one that has worked

without intervention, without noise, and most of the time

without even thinking about it. It was easy to improve for

free with local materials: snow. Without reinforced insulation

the other systems all together would have been unable to supply

reasonable conditions for life on board.

Ventilation : 28% of the energy consumed

corresponds to the heat losses through ventilation

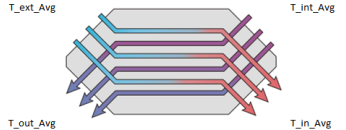

The diagram below shows the installation with the fresh air

intake and preheating with seawater (immersed tube) on the

left, the plate heat recovery system (in the middle) and the

warm cabin on the top right. The nomenclature of the temperature

probes will be used in the graphs below.

Installation in operation: example of

instantaneous values, typical winter day in December.

An efficient ventilation system must allow abundant ventilating

while keeping the heat inside. To meet this paradox a heat

exchanger is used to recover heat from the extracted air to

preheat the fresh air. A plate heat exchanger specially adapted

for use in the marine environment has been used.

Countercurrent plate heat exchanger:

80% efficiency, 90% with condensation (Klingenburg data)

Two simple precautions have ensured its smooth operation

despite the extreme cold where a conventional heat exchanger

would have quickly frosted, become clogged and useless:

- preheating the cold air by a tube immersed in relatively

warm seawater (-1.6° C), and

- a bypass reducing the flow of fresh air through the exchanger

to maintain a positive temperature; the air deficit passed

through the immersed bilge of the boat before infiltrating

into the cabins. In the absence of an operational anemometer,

the fraction of fresh air deviated by the bypass was evaluated

to 20% (observation of the regulating valve).

The ventilation system has been set to recover sensible and

latent heat by condensation. The ventilation rate was regulated

depending on relative humidity of the air inside the cabin

with a minimum ventilation below 50% and maximum ventilation

above 80% relative humidity, rarely reached (only when cooking

food or on wake up in the morning). A occasional monitoring

of the CO2 level allowed an indicative verification of the

air quality, usually situated at the upper normative limit

(1500 to 2000 ppm, day, excluding cooking).

The geometry of the ventilation system had to be adapted

several times to prevent the formation of frost and ice. Water

from condensation inside the heat exchanger was directed into

a bottle. Being exposed to extremely cold outside air temperatures,

the air outlet also had to be adapted to prevent blocking

by formation of ice.

The submerged tube was very effective, but mechanically insufficient

to withstand the severe stress imposed by the ice and was

torn apart before the end of the winter. This is a point to

improve. In the case of a construction on land, this tube

would be buried.. It is mandatory when operating the recovery

system at temperatures below -5° C.

Site of the air preheating tube by seawater

before immersion. The stones are used to sink the tube: diameter

70mm, submerged length 20m (photo Kalle Schmidt)

The graphs below show the temperatures at the inputs and

outputs of the exchanger:

T_air: outside air temperature (blue)

T_ext: air after submerged tube, at the inlet of the exchanger

(purple)

T_int: indoor air, in the cabin (red)

T_out: used air expelled from the heat exchanger (grey)

T_in: air at the exit heat exchanger, as blown into the cabin

- excluding bypass (light blue)

Overview of the ventilation system:

legend see diagram below ...

a) temperature gain due to the submerged tube

b) gain of the heat recovery system

c) submerged tube broken down at the end of February

Graph extracted over a week in early

January: legend see diagram below ...

Note: since the bypass is not connected to the air intake

tube in the cabin, the submerged tube failure does not affect

the temperature readings.

Unlike the initial project intending to make use of residual

heat at the outlet of the recovery system to produce drinking

water by melting ice or snow (see diagram above), the outlet

temperature was close to 0° C , too low to provide this

service. In return, the condensation water was collected in

the heat exchanger and used for washing hands.

Airlock and management of cold air inlets by door opening

:

To limit uncontrolled cold air intake, the initial project

included a winter entrance in the manner of an igloo tunnel.

Access was to be protected by a tent. After the violent storms,

the tents remained in their bags. It has also been found that

in very cold climates an entrance lock cannot be used to store

clothes. They must be dried in the heated zone at all times,

because even if perspiration is limited, the accumulation

of moisture is inevitable, making shoes and clothes gradually

ineffective.

We continued to use the usual insulated entrance door, however

reduced to a minimum opening of 60x60cm² located near

the floor, thus avoiding to release the hot air of the cabin

with each opening.

Water vapour management:

The gas stove (propane) and the kitchen are an important

source of vapours and odours. Also, to reduce over-ventilation,

we opted for low-temperature cooking, closed lids as much

as possible and made systematic use of the pressure cooker.

Odour management:

To preserve the quality of the air we gave up the traditional

oil lamp that can be found on many sailboats ... and in Greenland

homes. The toilets are equipped with an aspiration vent in

the composting unit which eliminates the unpleasant odours

at the base.

Conclusion :

Airtightness of the cabin (on a boat

that goes without saying) is essential to avoid the infiltration

of cold air. This sealing goes hand in hand with a ventilation

system because air quality is essential for the health of

the occupants, especially in confined spaces. We have been

able to show that a plate heat recovery system can be adapted

to very cold conditions and provide valuable service.

Heating

Mid-season:

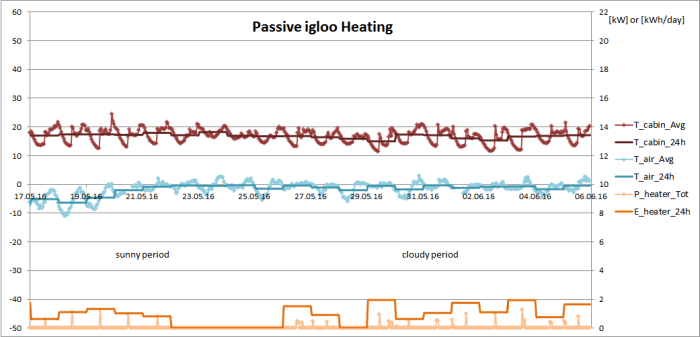

The following graph shows a typical heating pattern for

the end of May when climatic conditions were comparable to

European winters with temperatures between -5° C and +5°

C. During this period, a brief operation of the heater at

the time of waking allowed to raise the cabin temperature

from 13° C to 19° C and to stabilize naturally around

20° C during the day. In a context where we do not consider

to sacrify thermal comfort, this is excellent news and probably

the most important.

Graph from 17 May to 6 June 2016, a

period with temperatures comparable to the European winter,

between -10 ° C and + 3 ° C.

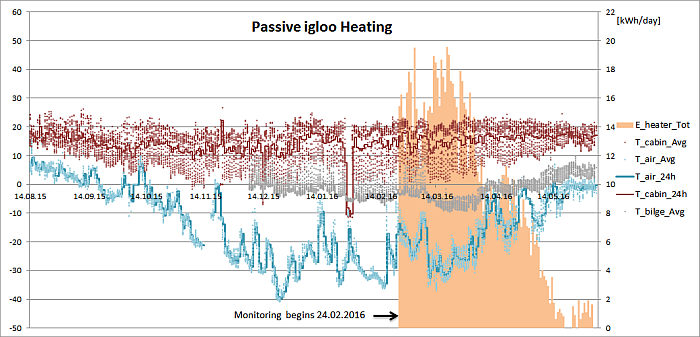

Winter:

Despite an unusually mild beginning of the year, the average

temperature was -26° C for the months of December to March

including three weeks with temperatures between -30° and

-40° C. During the winter 2015/2016 Greenland was swept

by heavy storms, with the exception of the Qeqertat region,

which experienced the most complete calms. Thus, from our

main wind-powered heating, we had to switch to 'plan B' and

rely on our propulsion fuel reserves to run the back-up system,

a forced-air diesel heater usually intended to dry the cabin

while sailing. The regulation is done by thermostat. The combustion

efficiency is 80%.

Winter 2015-2016 ; overview indoor and

outdoor air temperatures and daily heating energy

Despite the persistent lack of wind and the poor combustion

efficiency, winter heating consumption amounts to only 330

litres of diesel. This represents a fraction of the typical

Greenland homes in the Qaanaaq region (5-10 times less). In

the light of this observation, the goal of complete energy

self-sufficiency is possible, even in extreme cold climates

and without sun. Tthe wind generators operating under average

conditions, associated with a heat pump would have been sufficient

to provide 100% of thermal comfort(*).

(*) not available due to budget limitations.

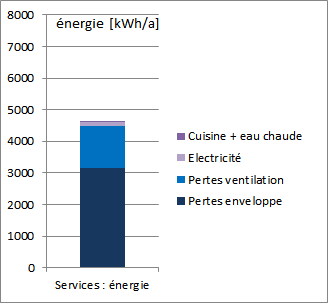

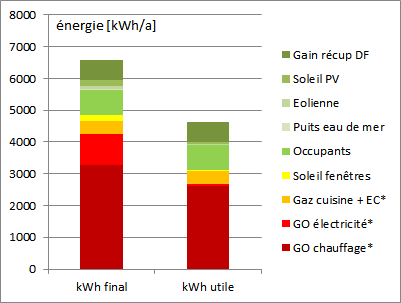

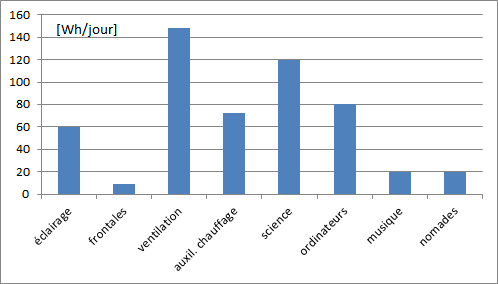

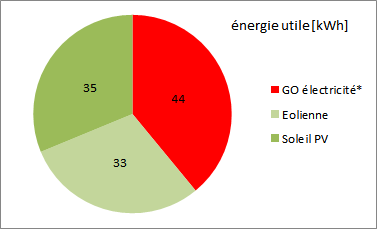

The following graphs show the consumptions (on the left)

and the energy sources (on the right) represented in final

energy (before conversion) and useful (actually used):

Energy by service |

Heat contributions [*] conventional

energies in red-orange, renewable energies in shades

of green and yellow

Heat contributions [*] conventional

energies in red-orange, renewable energies in shades

of green and yellow |

Wind and solar energy provide small overall contributions

and one can point out the poor efficiency of electricity production

(see explanations below). A significant contribution was the

heat produced by the occupants. In normal operation, 2 to

3 people permanently lived on board. During periods with numerous

visitors, for example during visits where 6 to 8 people were

on board, the heating system systematically stopped, even

in very cold weather.

Finally, the simple fact of shutting down the heating system

during sleep has saved ~25% of the heating energy. Thus we

enjoyed a comfortable temperature during the day, close to

20° C, and comfortable rest between 0° and 5°

C in warm sleeping bags * (see graph below).

(*) comfort temperature -20°C

Typical temperatures during a week in

March: temperatures, power and heating energy.

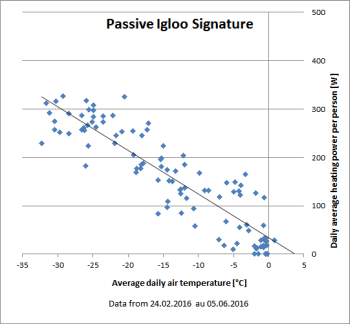

Energy signature

The energy signature characterizes the energy consumption

as a function of weather. It allows to define the temperature

from which an additional heating is required. It is obtained

by relating power or heating energy to the average daily outdoor

temperature, cf. graph below.

In very cold weather, the readings show that a heating power

of 300W per occupant is necessary to ensure comfort; 50W per

occupant is enough for periods that are comparable to climates

comparable to those in Central Europe. This is very little

and can easily be provided by renewable energies, which means

energy self-sufficiency.

The trend line places the non-heating temperature at the

intersection with the abscissa at +4° C. In practice,

above 0° C daily average temperature, no heating was required.

As a reminder: the average winter temperature in Central Europe

is above 0° C!

Average daily temperatures versus average

daily heating power per occupant.

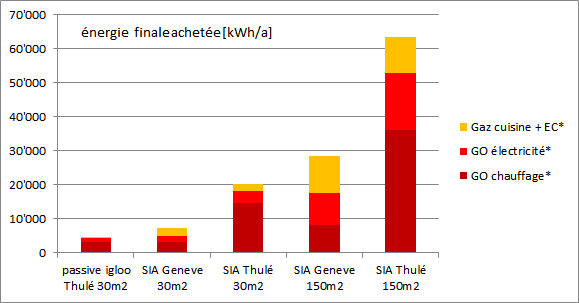

The performance of the passive igloo is highlighted by comparing

it to a dwelling built according to the mandatory standards

in Switzerland (limit values according to SIA 380/1):

SIA Geneva corresponds to a dwelling that has the same size

as the passive igloo, built according to regulations in the

climate of Geneva; SIA Thule is the same house in Arctic climate.

It is fairly representative of small Greenlandic houses imported

from Denmark.

SIA Genève 150m² corresponds to a dwelling whose

living space respects the recommendation of the Swiss regulations

for 2.5 inhabitants; SIA Thule 150m² is the same house

in Arctic climate.

Conclusions :

Designed according to the principles

of the passive building for temperate climates, the passive

igloo has shown that active heating is not necessary when

temperatures are above 0°C. A 'warm spot' remains however

desirable by allowing to meet temporary needs of physiological

or psychological order.

At a first approach, insulation should

limit transmission losses to less than 100 W per inhabitant.

The average U-value of the building envelope is calculated

by dividing this value by the difference between the design

indoor temperature and the average temperature of the coldest

week (winter) and the building envelope area per inhabitant.

Electricity : 4% of energy

Of course the boat could not be connected to any electrical

network. The limited availability of electrical energy has

forced us to optimize our electrical household: careful and

sober use, elimination of unnecessary and parasitic consumers,

charging nomadic devices only during periods of availability,

direct low voltage use wherever possible, otherwise by high

efficiency inverter (230V AC).

The daily consumption could thus be limited to only 0.5 kWh

for a 'household' of 2.5 occupants, which includes almost

permanent fixed and mobile lighting (head lamps), the ventilation

system, the power required by the forced air heater, scientific

instruments, two computers, music and various nomadic devices

as shown below.

Daily electric balance chart (winter)

The following systems have contributed to providing the necessary

electrical energy:

Electricity consumption for the period

of October 2015 to June 2016

Overview of the electrical system:

- wind: two-blade three-phase AC wind generator 1.5kW, 24V

+ an identical wind turbine for back-up

- sun: 4 mono crystalline solar panels of 50 Wp each, 12V

+ MPPT regulator (maximum power point tracker)

- back-up (diesel electricity): alternator on propulsion

motor 24V, 30A (point to improve)

- batteries: lead acid, liquid electrolyte 6x 4V 550Ah @

C20, series mounting

Back-up :

In the absence of wind and sun (Arctic night from October

to February) we had to make use of the propulsion engine alternator

for an almost daily charge of 30 to 45 minutes at 700W ...

a very inefficient way to produce electric power. It would

have been better to produce electricity with a dedicated heat-force

coupling system, i.e. a small diesel, gas or petrol genset

with recovery of combustion heat for space heating. The difficulty

inherent to these systems is the need to find a very small

model, < 800W of thermal power, and limited reliability.

With the return of the sun end of February there was abundance.

The small photovoltaic plant was largely sufficient to cover

all the needs. From that moment, cooking was made on an electric

induction plate, advantageously replacing the gas cooker.

Being excess production, this consumption does not appear

in the above accounts.

(application twilight,

clear sky model)

Conclusions :

Without electricity, few present-day

systems would work. In absolute quantity, electricity represents

a small amount of energy if produced and used with intelligence.

To ensure self-sufficiency, good complementarity of resources

is necessary. Anticipation and prior knowledge of local resources

are particularly important. This knowledge was lacking; for

the region that concerns us it just did not exist. Despite

these uncertainties, two thirds of the electricity needs have

been provided by renewable energy sources (wind and photovoltaics).

Daily life

Kitchen, water and hot water: 1.5% of energy

consumed

Cooking and hot water were either made on an induction plate

or a gas cooker powered by liquid propane in bottles, such

as purchased in Greenland. The bread was baked once a week

in a conventional gas oven. Due to the limited availability

of electricity, the induction plate has been little used during

winter. Most of the energy came from our stock of gas bottles,

two 10kg bottles. An unnoticed gas leak cost us an extra bottle.

Solid or liquid fuel would be more reliable, but much less

convenient.

Notes on optimizing cooking:

Among the efficiency measures, we implemented cooking methods

that significantly reduced gas consumption while avoiding

the unnecessary production of water vapour. The pressure cooker

has proved essential. It is the most efficient way to reduce

consumption by a factor of 2 to 4.

Energy being limited, it was necessary to make the best use

of it. To find out, we carried out comparative tests to bring

1 litre of cold water to boiling. The theoretical heat is

obtained by calculation.

With an efficiency of 85%, induction cooking proved very

interesting. This mode of cooking is best adapted to renewable

electricity (wind, sun, ...) provided that it is available

locally and in abundance. This was our case - when there was

wind or sun. For power supply one should consider the losses

of storage (batteries ~ 70%) and conversion (inverter ~ 90%).

When electricity is of thermal origin (power plant or genset),

the numerous transformations and transport make this system

potentially unefficient (15% to 20% overall efficiency) and

technically fragile (irreparable with on-board means).

The efficiency using the gas cooker amounts to only 15%,

but all the heat from cooking is beneficial to space heating.

In the end a not so bad solution. We also tested the various

plates (different diameters and powers), to associate with

each pan the fire that had the best performance: a little

saucepan on a big fire makes the flames go by; conversely

a large saucepan over a small fire lengthens the cooking time

disproportionately. Potential gain 10%.

The appropriate casserole:

Induction cooker: preferably use a lightweight pan with an

induction base (ferrous). It is possible to wrap the pan into

a blanket, even when cooking. Gain 10% to 20%.

Gas cooker: preferably use a cast iron pan. It will recover

some of the heat lost on the edges and avoids burning the

contents (thermal conduction by the edges). Gain 10 to 15%.

Fresh water:

The possibility of finding liquid drinking water in a nearby

lake was invaluable, avoiding the need to melt ice, a very

energy-intensive process.

There was no running water on board, neither cold nor hot.

The shower was done with a sop and a basin filled with hot

water: simple, effective, economical. Natural soaps limit

water consumption and pollution.

All in all, water consumption was 5-6 litres per person per

day, much of it for hot and cold drinks to hydrate ourselves

due to the very dry air of the Arctic.

Water was collected once or twice a week and stored in an

80-liter PE drum, placed in the warm and frost-free zone.

In addition, chunks of ice were melted to lengthen the water

collection intervals. This method is directly inspired by

local habits and customs.

Conclusions :

The potential for efficiency gains

is very large. However, cooking represents a small part of

the total consumption. The choice of suitable equipment and

good praxis are enough.

Laundry: 1.5% of energy consumed

During the first weeks, while we were cut off from the world,

we did the laundry on board, in small quantities to allow

drying inside the heated cabin. Once the link to the close

by village was restored we took advantage of the communal

laundry room.

Waste management and toilets

Waste management was first approached by promoting bulk or

large quantities of packaging, thus limiting the amount of

packaging. Then by a selective sorting: glass, metal, paper,

incinerable and organic matter.

The most important point was a strict separation of the organic

matter from the rest, the prerequisite to allow storage over

time without being inconvenienced by the development of bad

odours.

The dry composting toilets are worth mentioning since they

have been a real success. In particular the odour management,

incomparably better than any conventional toilet, was remarkable.

At the same time, the composter 'ate' the kitchen scraps

and pieces of paper and cardboard that were used to provide

composting in the absence of conventional materials (sawdust,

wood chips, ...). Thus, through rigorous sorting and the efficient

management of compostable materials, less than a bag of 20

litres of dry and clean incinerable waste were produced per

month. These could be stored indefinitely while waiting for

the next call to a place equipped with appropriate waste handling

facilities.

The composter contents were transferred every 3-4 weeks into

a bag stored outside and so immediately frozen. As soon as

summer came back, the post-composting was done at the foot

of a sunny and warm rock with an abundant and opportunistic

fauna of flies and worms. Compared to a flush toilet system

(a), this system has avoided producing 18'000 litres of problematic

black water impossible to manage in the long term. Extrapolated

to 12 months, this represents less than 200 litres of fertile

compost that could be returned to the environment and 1000

litres of urine collected and assimilated in small quantities

into seawater (b). Quantities apply for a crew of 2.5 people

on average.

Comparative WC (a) - TS (b) for one

year and 2.5 people: 1 cube = 1000 litres

The model used on board are dry toilets of the market. They

deserve some improvements in ergonomics including the urine

separation device and the handling of the compost bin.

All that remains were metals, glass and some plastic containers.

Once cleaned and compacted these materials were stored and

carried to the first available recycling point. The volume

and the weight were no problem, being in all cases well below

the initial volume shipped.

Conclusions :

The constraints made us take an important

step towards composting toilets which proved to be very suitable

despite our situation which does not predispose to this type

of system, in particular because of the cold which is not

favourable to the processes of biological transformation.

During navigation, we still use the

classic marine toilet system (flush seawater), more suitable

to absorb the flow of a variable and numerous crew.

Finally, the notion of waste should

be substituted by 'recyclable materials'. If properly managed

from the beginning it is a non-problem.

Nutrition and more

Provisioning in Malmö: second third

of food for one year (photo Kalle Schmidt)

Providing food for 12 months is not a simple task. It represents

nearly a ton of food that must be stored for a long time and

allowing a healthy, complete and balanced diet. Half of it

was used by the the summer crews (10 persons for 2 months),

the rest by the winter crew (2 persons for 10 months).

Not being enthusiasts of freeze-dried and pre-cooked or frozen

food, we found inspiration in the traditional cuisine based

on legumes and cereals, the most complete possible. Dried

fruits, vegetables and mushrooms brought variety, as well

as a very complete assortment of spices.

An additional caloric basis consisted of honey, olive oil,

butter and a big cheese wheel. Cabbage and fresh onions were

kept until February. With the return of the sun we were growing

seeds.

To avoid the risk of a vitamin deficiency we supplemented

our diet with a daily vitamin capsule and vitamin D during

the night months. Finally, a fish or occasional hunt contributed

to an exemplary diet. The best proof: we have not developed

any culinary fantasy ...

Conclusions :

Simple and adapted solutions do exist.

It is necessary to leave the habits of the precooked dish.

Conservation has been the key to our diet. Many solutions

exist since the dawn of time. They are sound sources of inspiration.

Excerpt from the logbook "Today,

June 20, fresh food makes us dream. The supply ship from Denmark

will arrive in two weeks!"

Isolation

We were prepared for isolation. The key word was self-reliance,

from the level of knowledge to carrying out the project, skills,

tools and spare parts to repair just about anything. However,

we underestimated the importance of carrying reference books

and dictionaries. Not being equipped with satellite communication

systems, the toughest was the period of icing in where we

were cut off from the world during 3 months of which 2 without

being able to leave the perimeter of the boat.

Darkness

Contrary to popular belief, it is not night for four months.

There are magnificent twilights, moonlight, stars, and sometimes

aurora borealis to brighten up the sky. All on a background

of snow and ice that amplify the light. But this spectacle

is only visible for those who do not abuse of artificial lighting.

Thus we experienced the return of the sun not as a liberation,

but rather as the augury of a new chapter, as exciting as

the previous ones.

See twilight...

Conclusions

There are still some things to improve,

there always will be(!), but the 'passive igloo' experience

shows that it is possible to create a habitat that is close

to self-sufficient in terms of energy supply while remaining

simple and affordable for the coldest climates on earth.

An outstanding thermal insulation is

the basis of a comfortable and durable habitat. This is a

prerequisite on the way towards renewable energies. It is

also a life-insurance in case of supply problems because it

makes implementation towards alternatives possible and affordable.

The expedition was a laboratory in

a hostile environment that does not allow any missteps. At

times the commitment was complete and required absolute reliability

of the systems. The only ones to be perfectly reliable were

the passive systems, to begin with the thermal insulation.

We were able to experiment each subsystem

in detail in the context of the harsh conditions of real-world.

And in turn each system has been pushed to and beyond its

limits.

Finally, the passive igloo was a most

demanding scenario because of its small size and subjected

to innumerable additional constraints related to the marine

environment - after all it is also a sailboat. Therefore,

what has been possible for the passive igloo will be much

easier for a land based construction. And the bigger the construction,

the easier it will be to achieve these goals because the form

factor is favourable.

Due to experience and good preparation

we have never suffered from the cold. Whether it's the boat

or the clothes, the organization or the equipment to cope

with the cold, everything has added to make the winter a pleasant

and rewarding experience at any time. But we also learned

from local people. The most beautiful sign of confidence in

what we were doing was entrusting their children to spend

the night aboard.

Today, we are looking forward to build

on the experience of the passive igloo, by developing the

concept around self-sufficient terrestrial habitats in the

Arctic or in the high mountains.

How to go further?

Heating energy accounts for almost half of the primary energy

imported into Switzerland. The situation is comparable in

other European countries.

Knowing the limits of non-renewable energies and the harmful

effects on the environment of their inconsiderate consumption,

it is an important lever on which we must act. And we can:

The experience of the passive igloo shows that it is possible

to reduce this consumption drastically. This knowledge is

applicable to any new construction. The responsibility to

ensure the implementation rests with all actors: communities,

project owners, architects, builders, operators, inhabitants.

Teaching has an important role to play too.

Built to these standards of design, the buildings of the

future will not only be more ecological. They will also be

more resilient, capable to adapt to the uncertainties and

surprises that the future holds for us. The prerequisite will

be simplicity, synonymous of economy and sustainability.

High efficiency is a prerequisite on the way to renewable

energies: it is much more economical and ecological to reduce

needs than to build ever bigger solar farms, wind farms, dams

...

|

|

The arrows on houses represent the

energy needs for heating,

hot water and electricity.

At equal service, efficiency measures aim to reduce

needs.

Self-sufficiency means substitution with renewable

energies.

The combination of both is necessary to achieve

efficient and affordable homes.

Sobriety questions our real needs. More quality

and less quantity.

|

There is no valid excuse for not making contemporary buildings

energy self-sufficient. It is all the more urgent since these

buildings will probably still exist in a generation or two,

in a future where 'easy' energy will be past.

Only simple and robust solutions with a short ecological

return time will have to be used to achieve this goal. These

buildings will distinguish themselves neither by their appearance

nor by their cost of construction. Passive devices, insulation

first, are neither spectacular nor sophisticated. It is as

simple as integrating the right strategies from the beginning.

They are an essential project condition. A building must not

only withstand gravity, use and boredom (firmitas, utilitas,

venustas *), it must also withstand time and the future.

[*] Vitruvius: strength, utility, beauty

The difficulty of rehabilitating existing buildings that

have become obsolete shows how important a proper vision for

the future is. This is also important to ensure the sustainability

of real estate investments. It shows that there is no time

to waste. We must act today.

If our world is not yet ready to make concessions on quantity,

sobriety will become a most important lever. This cannot be

achieved without providing quality. It's about cultivating

quality before quantity, a paradigm shift.

Often the fear of change is more painful than the change

itself. But this change is possible.

Peter Gallinelli, Greenland, Nanuq's cove,

June 2016

|